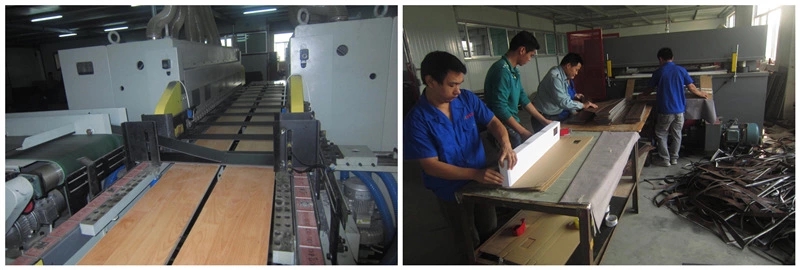

It can save 30% of the total cost when buying commercial pvc roll directly from factory!

|

Available Size of vinyl flooring roll

|

1.83x30mts/2x30mts/2.5x30mts/2x20mts/1.83x20mts,etc.

|

|

Thickness of vinyl flooring roll

|

PVC: 0.35mm, 0.4mm, 0.5mm, 0.6mm, 0.8mm, 1.6mm, 2.0mm

|

|

PET: 0.35mm, 0.4mm, 0.5mm, 0.6mm, 0.8mm, 1.6mm, 2.0mm

|

|

|

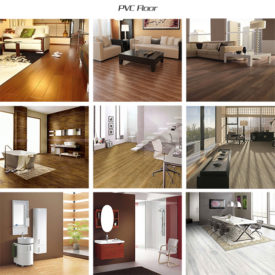

Surface of vinyl flooring

|

Deep embossed / Registered emboosed / Sawn cut / Rough tick / Hand scrape / Crystal

|

|

Application of vinyl flooring

|

linoleum pvc floor roll and Wall

|

|

Warranty

|

10-15 Years

|

|

Residential Warranty

|

10-15 Years

|

Construction requirements of pvc homogeneous vinyl flooring roll:

1. Before the paving of the concrete dense foam pvc flooring roll, the mortar C10 must be leveled 15-20 days in advance, and the leveling height is 5 mm lower than the ground design height. The leveling surface is glossy.

2. The flatness of the vinyl commercial roll plastic to the leveling of the foundation floor requires a height error of less than 2 mm per 2 meters.

3. The concrete and screed must be sufficiently dry before the vinyl flooring roll can be installed. It usually takes 15-20 days to construct. The moisture content of the entire surface does not exceed 5%.

4. The leveling layer must have sufficient bearing capacity, and there should be no cracks, empty drums and sanding of the pvc flooring roll. The strength of the base cement must be greater than 10Mpa.

5. The foundation vinyl flooring roll needs to be clean, free of grease, paint, glue, cement lumps, etc.

6. The vinyl flooring roll line is constructed after the floor is installed. Pay attention to protect the installed coil floor

during construction.

7. Where the coiled floor is connected to other grounds, the other floors must be installed and edged to ensure a smooth connection.

1. Roll up half of the coil and start to glue on the roll flooring. Note that the coated area per time does not exceed half of the area of a single coil. Cover the floor and repeatedly compact it with a special roller press. Note that when rolling, first roll horizontally and then longitudinally to squeeze out the residual gas under the vinyl flooring roll. The other half is the same as above.

2. When laying the second row of vinyl floorings roll, pay attention to keeping the direction of the vinyl flooring roll consistent. The adjacent floor is laid to overlap 15mm, then draw with a line drawing and cut.

3. To seal the seams, remove dust and debris from the vinyl flooring roll and the back of the coil before applying the glue, and leave a coin-thick seam between the seams to facilitate seaming.

1. Select PVC vinyl flooring roll produced by regular manufacturers to ensure fire protection and environmental protection meet national standards.

2. According to the flow rate of the place of use and the design life, choose the appropriate LVT roll flooring. This link is very important. The material selection is inadvertent, which directly leads to the continuous quality problems in the subsequent use of the vinyl floor roll.

3. Use professional staff to install PVC lvt flooring roll to ensure the smooth and smooth treatment of the ground floor, the correct selection of floor glue, and the reasonable laying of the indoor vinyl flooring roll, without leaving any quality hazards.

4, PVC spc flooring roll installation is completed, to do the vinyl flooring roll maintenance, care work, PVC flooring roll easy to care, but can not be ignored, reasonable maintenance, care work can effectively extend the life of PVC flooring roll.